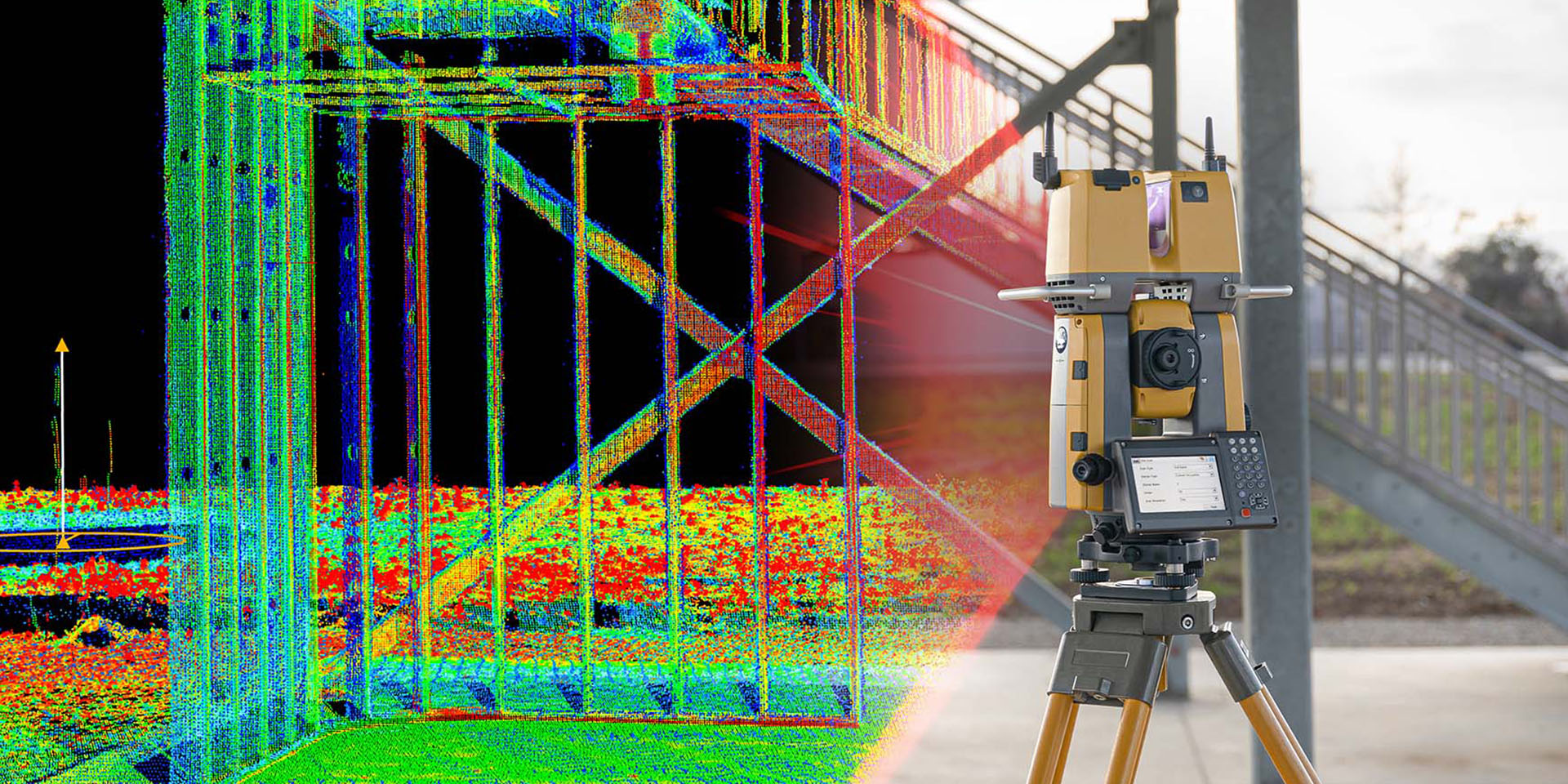

This solution streamlines as-built 3D data and QA/QC workflows to identify construction errors and variances, almost in real-time. The GTL adds the power of laser scanning to a robotic total station so you can capture the as-built data with the same instrument you use for layout. Combine the GTL with Verity’s automated QA/QC workflow to compare the as-built data against the BIM design model and quickly spot variances—so you can check all your work every day and catch errors faster.

Improving QA practices with the latest technology

Construction experts estimate that rework and delays increase costs about 20% over budget. Traditional spot checking of completed work leaves verification gaps that can result in significant cost overruns and lost profits. Fortunately, the Topcon construction-verification solution can help.

About the workflow

Comparing the scan data with the BIM model enables construction-verification workflows that are up to 10 times faster than traditional spot-checking methods.

Market segments

The complete solution

The workflows that control and manage data and deliverables set the GTL solution apart

The GTL solution replaces spot checks with a revolutionary process that does construction verification in hours instead of days, dramatically reducing errors and cost.

What is Construction Verification?

MAGNET and GT series building construction testimonial

Workflow benefits

How does it work?

SCAN/LAYOUT

PROCESS

AS-BUILT & VERIFY

Related offerings

Get in touch

Thank you! We will be in touch.