About the floor flatness and levelness workflow

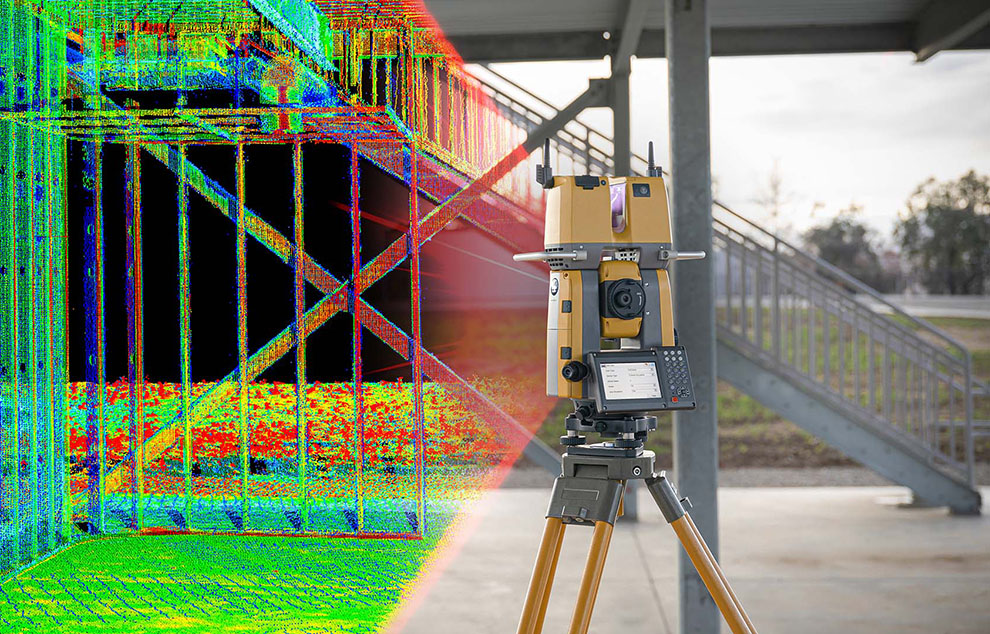

This integrated QA workflow generates industry-compliant, floor-deviation reports in-house, providing fast, actionable insights that prevent costly delays. The GLS and GTL scanners accelerate data collection and processing for floor-flatness analysis. Combine with Rithm for Naviswork to perform FF/FL QA in minutes, empowering your team to produce industry-compliant reports and control the project schedule.

How does it work?

1. Scan wet or dry concrete

2. Process data

3. Run Rithm analysis

4. Generate FF/FL report

“One person can do the conventional topo in half the time. And we no longer have to spend an extra day for the flatness and floor levelness report.“

– Edgar Valenzuela, Field Engineer, TAS Concrete

Workflow benefits

“I’m going home and I am not coming back because I know that this project is perfect. I am going to sleep well tonight.”

– Tony Mendoza, Owner, M4 Concrete and Drywall

Case studies

Instruments

Related offerings

Get in touch

Thank you! We will be in touch.